Why You Required Stretch Wrapper Repair Work: Discovering Its Function in Ensuring Packaging Quality and Security

Stretch wrappers play an important function in the packaging procedure by making sure the stability and honesty of bundled items. They can come across various problems that demand timely repair services. Overlooking these repair work can bring about significant inadequacies and potential item damage. Comprehending the implications of stretch wrapper maintenance is crucial for any kind of business. This conversation will explore exactly how regular repairs add to packaging quality and safety and security, eventually affecting the entire supply chain.

Recognizing the Significance of Stretch Wrappers in Product Packaging

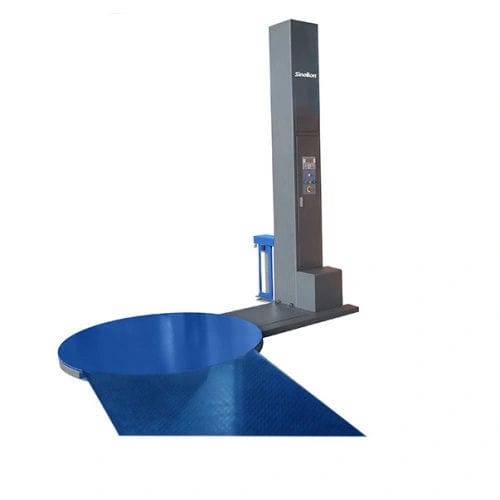

Although usually neglected, stretch wrappers play a crucial duty in the packaging procedure for different sectors. These machines ensure the safe and secure bundling of items, improving security and protecting things during transportation. By tightly covering items in stretch movie, they decrease the risk of damages from changing or environmental factors.In sectors like food, drugs, and production, reliable packaging is crucial for maintaining item integrity and security (stretch wrapper repair). Stretch wrappers add to this by decreasing the likelihood of contamination and perishing, thereby extending shelf life. Furthermore, their effectiveness promotes cost-effectiveness; companies can streamline packaging operations, lowering labor expenses and time.Moreover, stretch wrappers can accommodate different item shapes and sizes, making them functional devices in product packaging. Their capability to satisfy various lots makes sure that also irregularly designed things are protected correctly. To sum up, the value of stretch wrappers can not be underestimated in the quest for quality packaging services

Common Problems That Require Stretch Wrapper Fixing

Stretch wrappers, while crucial for preserving packaging honesty, can run into various operational concerns that necessitate repair. Typical problems consist of inconsistent stress, which may bring about damaged or loose loads, endangering item defense throughout transportation. In addition, malfunctioning sensing units can disrupt the covering process, resulting in uneven application of stretch movie. Worn-out rollers or belts might cause slippage, impeding the wrapper's efficiency and triggering hold-ups in production. Issues with the control system can lead to inappropriate setups, impacting the total covering high quality. Dust and particles accumulation in mechanical parts can additionally result in deterioration, requiring normal maintenance to stop breakdowns. Recognizing these problems at an early stage is necessary, as prompt fixings can substantially expand the lifespan of the stretch wrapper and preserve suitable packaging criteria. Addressing these typical concerns guarantees that services can remain to run efficiently and deliver items securely.

The Influence of Neglecting Repairs on Packaging Performance

Enhancing Product Safety And Security Through Regular Upkeep

Normal maintenance of stretch wrappers is vital for preventing packaging failings that can compromise product safety. By resolving deterioration quickly, firms can significantly decrease item damages and assurance that equipment runs regularly. This proactive method not only safeguards the honesty of the products however additionally enhances general operational effectiveness.

Preventing Product Packaging Failures

Reliable upkeep of product packaging equipment is necessary for protecting against failings that can endanger product security. Normal examinations and prompt repairs of stretch wrappers help identify potential problems before they rise into significant troubles. When stretch wrappers are well-maintained, they work at peak efficiency, making sure that items are safely wrapped and safeguarded throughout storage space and transportation. Preventative upkeep timetables can considerably lower the probability of mechanical failures, which commonly cause product packaging errors or malfunctions. By purchasing routine checks, companies not only guard their items yet additionally improve their overall operational efficiency. This positive method lowers downtime and cultivates a culture of security, eventually adding to greater customer complete satisfaction and rely on the brand. Normal upkeep is as a result a foundation of efficient packaging administration.

Reducing Item Damage

Preserving stretch wrappers is important for minimizing item damages and making certain security during handling and transportation. Routine upkeep of these devices assists identify and remedy small problems before they rise right into significant problems, consequently protecting the integrity of the wrapped items. When stretch wrappers run at peak efficiency, they provide constant stress and insurance coverage, which lessens the threat of tons changing during transit. stretch wrapper repair. This reliability avoids prospective problems that could occur from incorrect wrapping strategies, such as tearing or squashing of packaging materials. Furthermore, well-maintained stretch wrappers add to a much safer workplace by minimizing the chance of accidents triggered by unsteady or poorly wrapped tons. Ultimately, thorough upkeep plays a crucial function in securing both products and employees throughout the supply chain

Guaranteeing Consistent Efficiency

Constant performance of stretch wrappers is vital for boosting item safety throughout the supply chain. Regular upkeep plays a crucial duty in ensuring that stretch wrappers operate successfully, reducing the chance of equipment failures that can endanger packaging stability. By consistently evaluating and servicing these machines, services can recognize potential concerns prior to they intensify, therefore reducing downtime and stopping product damages. Additionally, properly maintained stretch wrappers apply consistent stress to product packaging materials, making sure that loads remain safe throughout transportation. This integrity not just shields items from falling or moving yet also fosters consumer rely on the brand. Inevitably, focusing on constant efficiency with routine maintenance safeguards item quality and enhances security for both consumers and makers alike.

Cost-Benefit Analysis of Buying Repair Service Providers

Purchasing repair work solutions for stretch wrappers can cause significant long-term cost savings by prolonging equipment life-span and reducing the need for pricey substitutes. Furthermore, prompt fixings help avoid he said tools downtime, ensuring regular manufacturing flow. Enhanced product packaging performance additionally adds to overall operational efficiency, making repair work services a strategic consideration for services.

Long-Term Savings Potential

Reviewing the long-lasting cost savings capacity of stretch wrapper repair services reveals substantial expense benefits for services. By purchasing timely repair work, companies can extend the life-span of their equipment, minimizing the frequency of expensive replacements. In addition, efficient stretch wrappers lessen product waste and guarantee constant item quality, which subsequently enhances consumer contentment and reduces returns.Moreover, a well-maintained stretch wrapper can result in reduced power usage and reduced operational prices. Repair solutions usually come with warranties that secure against future costs, offering added economic protection. In general, the aggressive approach of purchasing repair service solutions translates right into not only improved efficiency however also considerable cost savings gradually, making it a critical monetary decision for services going for sustainability and efficiency.

Stopping Tools Downtime

Prompt fixings to extend wrappers can significantly minimize devices downtime, an aspect that straight influences operational effectiveness and productivity. When stretch wrappers breakdown, manufacturing lines can stop, causing hold-ups in fulfilling orders and potential loss of profits. Buying repair work services guarantees that equipment continues to be in top functioning condition, lessening the danger of unexpected breakdowns. This positive technique not just saves money in the future however additionally improves labor force spirits, as staff members can function without the stress of malfunctioning equipment. Furthermore, preserving regular procedures enhances customer fulfillment with trusted delivery times. Eventually, the cost-benefit evaluation of spending in repair service solutions highlights the relevance of avoiding downtime, as it cultivates a more efficient and stable workplace.

Improved Product Packaging Effectiveness

A substantial enhancement in product packaging performance can be achieved via the effective repair service of stretch wrappers. Well-kept stretch wrappers maximize material usage, minimize waste, and warranty constant application of safety film. stretch wrapper repair. By spending in repair service solutions, companies can lengthen the life of their tools, minimizing the demand for pricey replacements. This aggressive technique not only keeps efficiency yet likewise reduces labor expenses connected with hand-operated re-wrapping or damaged pallets. Furthermore, boosted equipment efficiency can result in faster packaging cycles, enhancing general throughput. Eventually, the cost-benefit analysis discloses that spending in stretch wrapper repair work services yields significant returns by enhancing operational effectiveness, protecting item integrity, and assuring that product packaging procedures align with industry criteria for quality and safety and security

Picking the Right Provider for Stretch Wrapper Repair Works

Just how can one assure that the selected company for stretch wrapper fixings satisfies both quality and efficiency requirements? Selecting the right company needs cautious factor to consider of numerous elements. First, evaluating the provider's experience and proficiency in stretch wrapper fixings is important. A reputable company with a tried and tested performance history can offer assurance of their capabilities. In addition, getting references or reviews from previous clients can use insights right into the supplier's dependability and solution quality.Furthermore, evaluating the variety of services used is necessary. An extensive repair solution that consists of diagnostics, maintenance, and parts replacement can facilitate a lot more effective procedures. It's likewise suggested to make inquiries about the company's action time and schedule for emergency situation repairs, as downtime can significantly affect performance. Ultimately, reviewing cost-effectiveness without jeopardizing top quality will assist in making an educated choice that straightens with operational requirements and spending plan constraints.

Ideal Practices for Preserving Your Stretch Wrapper Devices

Keeping stretch wrapper tools click now is important for ensuring peak efficiency and longevity. Routine evaluations should be conducted to determine any signs of wear or damage, especially in essential parts such as the film carriage, rollers, and motors. Maintaining the maker clean and totally free from particles is crucial, as dirt can cause mechanical failures and irregular wrapping results. Lubricating relocating components according to the producer's standards will boost performance and minimize rubbing. In addition, drivers must be trained to make use of the devices correctly, as incorrect usage can result in premature wear. It is advisable to establish a regular maintenance routine, including look for electrical connections and software application updates. Preserving an ample supply of substitute components on hand can avoid downtime throughout unanticipated repair services. By sticking to these finest techniques, firms can guarantee their stretch wrappers operate efficiently and add to general packaging high quality and security.

Regularly Asked Concerns

Exactly how Typically Should I Schedule Stretch Wrapper Upkeep?

Regular upkeep for stretch wrappers ought to be arranged every 6 months. Increased use or details operational demands might necessitate more regular checks to ensure peak efficiency and stop unanticipated breakdowns, improving total performance.

Can I Fix a Stretch Wrapper Myself?

Fixing a stretch wrapper separately is possible, however it calls for technological expertise and competence. Errors can cause additional damages, so getting in touch with a specialist or describing the producer's guidelines is commonly suggested for effective repair work.

What Are the Indicators My Stretch Wrapper Requirements Repair Service?

Signs that a stretch wrapper requires fixing consist of irregular covering stress, noticeable damage to the film, unusual noises during procedure, regular jams, and failure to appropriately secure tons. Prompt attention is important to maintain efficiency and safety and security.

How much time Does a Common Stretch Wrapper Repair Service Take?

The period of a normal stretch wrapper repair service varies, frequently taking between one to 3 hours, depending upon the complexity of the issue. Variables such as components availability and specialist know-how likewise affect repair service time.

Are There Guarantees for Stretch Wrapper Fixing Solutions?

Warranties for stretch wrapper repair service services commonly differ by copyright. Generally, reputable companies provide restricted guarantees covering parts and labor, making certain consumers obtain trustworthy service and defense against problems or concerns occurring post-repair. Stretch wrappers, while crucial for maintaining packaging integrity, can run into different operational issues that necessitate fixing. Identifying these concerns early on is essential, as click for source timely repair work can considerably extend the lifespan of the stretch wrapper and maintain suitable packaging criteria. Spending in repair solutions for stretch wrappers can lead to substantial long-term financial savings by expanding equipment life expectancy and reducing the need for costly substitutes. Additionally, reliable stretch wrappers lessen material waste and assurance regular item top quality, which in turn boosts consumer contentment and lowers returns.Moreover, a properly maintained stretch wrapper can lead to reduced power usage and reduced operational prices. A considerable improvement in product packaging efficiency can be achieved through the reliable repair of stretch wrappers.

Comments on “How regular stretch wrapper repair is vital to operational success”